Jindun has a professional technology research and development center, as well as an advanced mold design and manufacturing center that enables the production of new molds within 20 days. We are equipped with advanced production equipment for casting, heat treatment, surface coating, CNC machining, and assembly, which can realize to produce 200,000 wheels per month. Our company has established a quality inspection center to strictly control the quality inspection of the manufactured wheels. At this center, we are equipped with spectrometers, impact testing machines, fatigue testing machines, a full set of chemical analysis testing equipment, and other advanced testing equipment to ensure that each manufactured wheel is high-quality and reliable.

-

Customer Requirements

Customer demand is the orientation of Jindun’s survival and development, while customer satisfaction will be our greatest pursuit. Our attitude is to treat every visiting customer seriously and sincerely.

Read More -

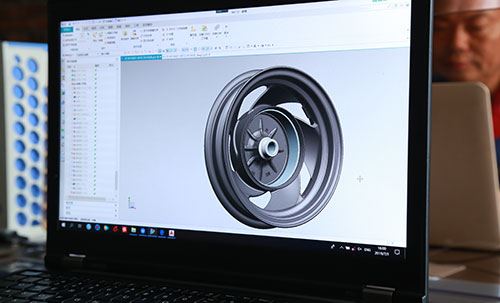

Mold Design and Manufacturing

Jindun has an independent quality technology department, which integrates technology development and quality control to produce high-quality, high-efficiency wheels. The technical manager will design beautiful, high-performance, light-weighted wheels according to the needs of customers.

Read More -

Heat Treatment

Aluminum wheels can be heat treated to improve the performance, mechanical properties, size and shape accuracies. The following types of heat treatment processes are available based on your needs.

Read More -

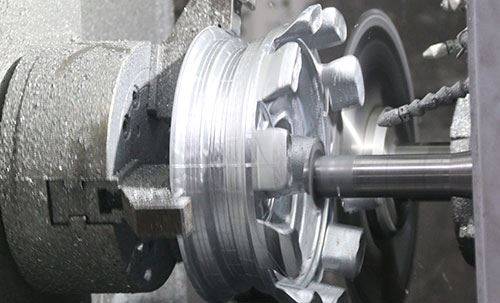

CNC Machining

CNC machine tools are used for further processing of the semi-finished aluminum wheels to ensure that the finished product has precise dimensions and smooth edges.

Read More -

Surface Treatment

Jindun is able to produce aluminum alloy wheels with various surface treatment needs with a full set of pretreatment machines, painting equipment, and powder coating equipment.

Read More -

Quality Control

Manufacturing with the best quality is our core value, and we are committed to creating aluminum wheels with the highest safety rating.

Read More

Customer Sample

The manufactured wheel will go through a series of production steps of design, mold manufacturing, casting, heat treatment, surface coating, CNC machining, and assembly. After passing the product quality inspection, the samples will be shipped by express delivery to reach the customer at the fastest speed for confirmation.

Mass Production

After the customer confirms the appearance and quality of the sample, we will proceed with mass production.